Members of the Welping team are learning product knowledge of butt fusion machines in the workshop, and exchanging ideas about products, markets, and services, all with the aim of better supporting our customers.

Members of the Welping team are learning product knowledge of butt fusion machines in the workshop, and exchanging ideas about products, markets, and services, all with the aim of better supporting our customers.

With the increasing popularization of pe pipe, pe pipe is being used in various fields such as petroleum gas, liquefied petroleum gas, water, drainage, electric power engineering, how to ensure the quality of engineering construction, buy good pe pipe, how to use pe pipe heat fusion welding machine in the engineering construction, how to skillfully…

Site inspection at welping workshop In the WELPING workshop, our team carefully examined every detail of the machine’s exterior, to guarantee that the products we provide to our valued customers are nothing short of exceptional. Our commitment to good quality is what drives us in the plastic welding industry, especially in HDPE pipe but fusion…

I. Accuracy and Stability Domestic Pressure Sensors: Imported Pressure Sensors: II. Materials and Manufacturing Processes Domestic Pressure Sensors: Imported Pressure Sensors: III. Price and Cost-Effectiveness Domestic Pressure Sensors: Imported Pressure Sensors: IV. After-Sales Service and Support Domestic Pressure Sensors: Imported Pressure Sensors: V. Application Scenarios Domestic Pressure Sensors: Imported Pressure Sensors: Conclusion Choosing between domestic…

I. Equipment Appearance and Basic Configuration Check Equipment Appearance Check: Basic Configuration Check: II. Electrical System Check Power Supply Check: Grounding Check: Electrical Control System Check: III. Hydraulic System Check Hydraulic Oil Check: Hydraulic Pipeline Check: Hydraulic Cylinder and Pump Check: IV. Heating System Check Heating Plate Check: Temperature Sensor Check: V. Mechanical System Check…

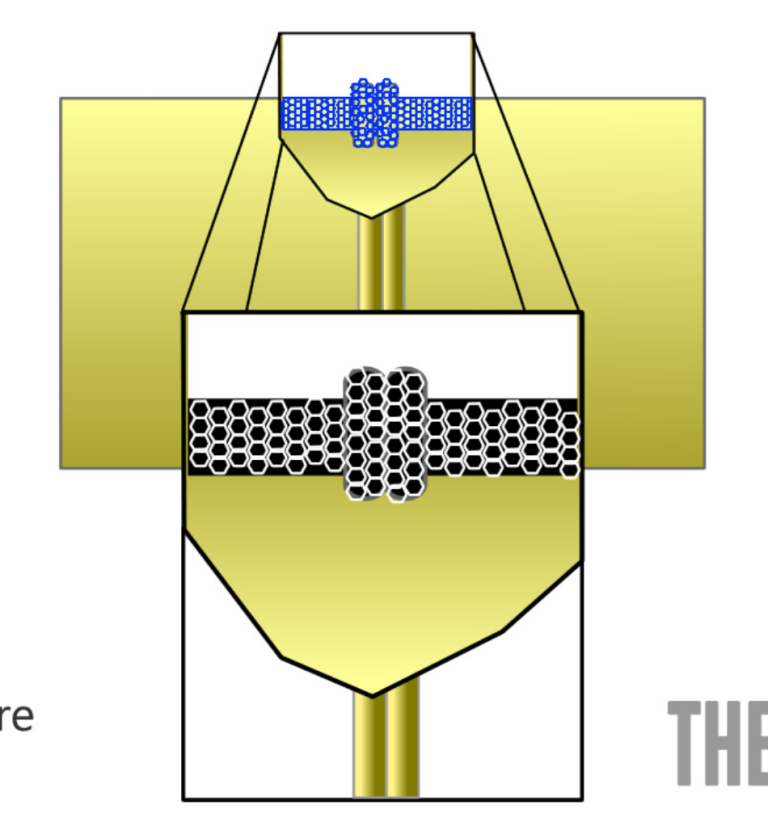

First of all, let’s talk about the heat fusion theory of butt welding machine. The pipe fusion process associated with Welping butt fusion machines is a widely accepted process that joins two pieces of thermoplastic pipe or pipe fitting together with heat and pressure. While commonly associated with high-density polyethylene pipe (HDPE), our machines are…

Butt fusion welding machines are essential tools in the welding of thermoplastic pipes. These machines operate by heating the ends of two pipes simultaneously until they reach a molten state. The pipes are then pressed together under pressure, resulting in a fusion of the material that creates a strong, homogenous joint. The choice of materials…