Today, Let’s discuss the 9 major changes in our new butt welder.I’m sure it’ll be a great partner in your work.

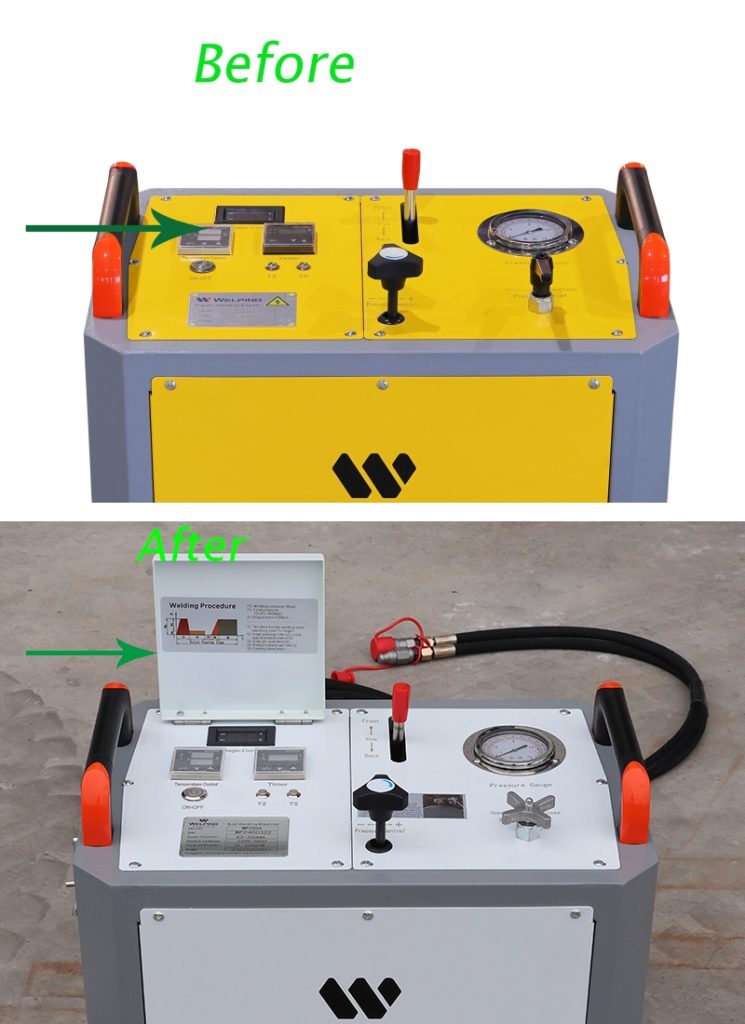

1.A pro HydraThe back of the frame is added with a supportive round steel tube, which makes the structure more stable and effectively reduces the vibration of the machine body during the cutting process.ulic station added electronic instrument cover, waterproof and dustproof.

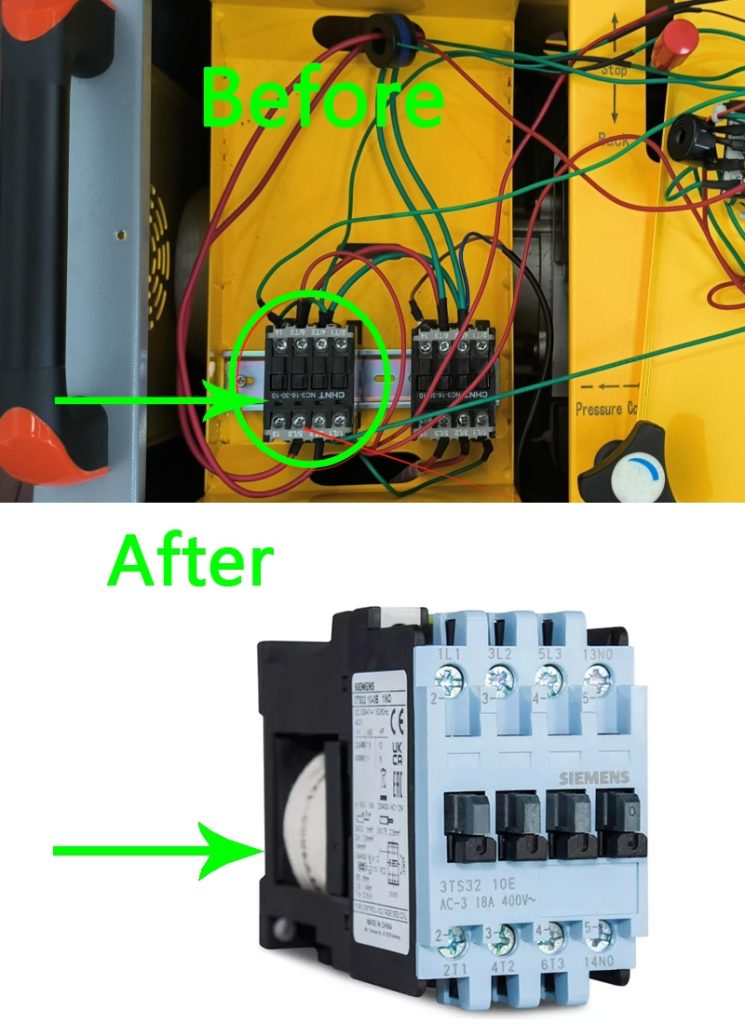

2.A pro hydraulic station is upgraded with Siemens contactor, which enhances the reliability and durability of the equipment, reduces the failure rate, improves the production efficiency, and ensures more stable welding quality.

3.A pro butt welders can be equipped with an optional accumulator, which provides a more stable pressure output, reduces energy consumption, improves weld results, and provides emergency power in the event of a power failure to ensure process continuity and safety.

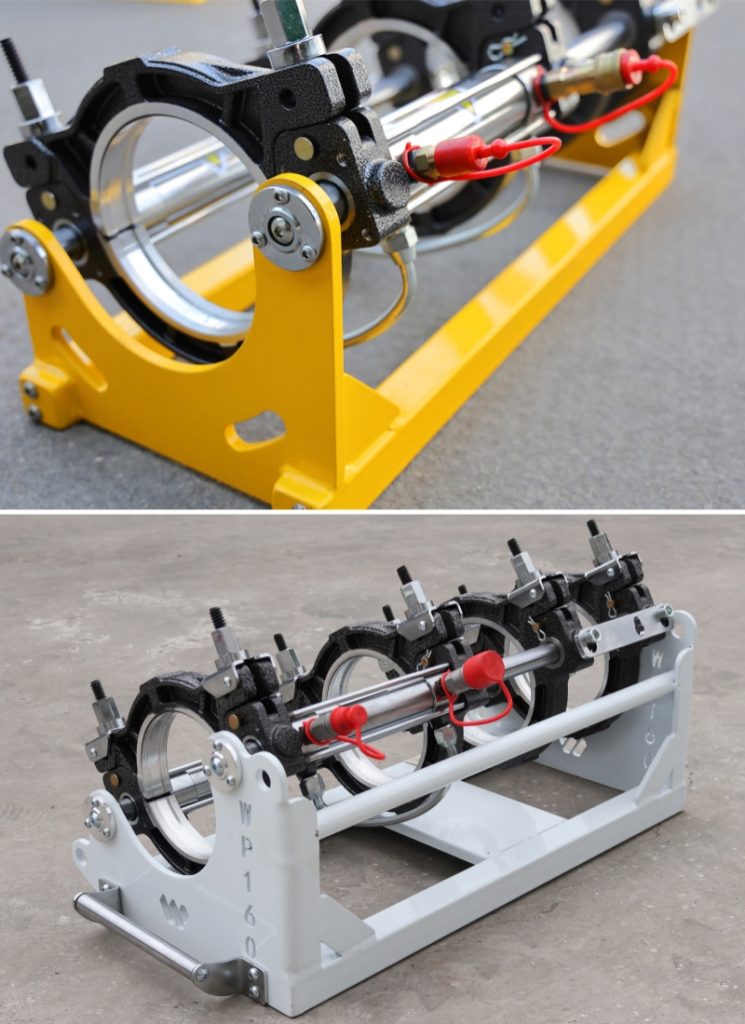

4.The back of the frame is added with a supportive round steel tube, which makes the structure more stable and effectively reduces the vibration of the machine body during the cutting process.

5.The side of the frame is hollowed out and engraved with a logo pattern, which not only enhances the aesthetics of the equipment, but also reflects the uniqueness and professionalism of our WELPING machines.

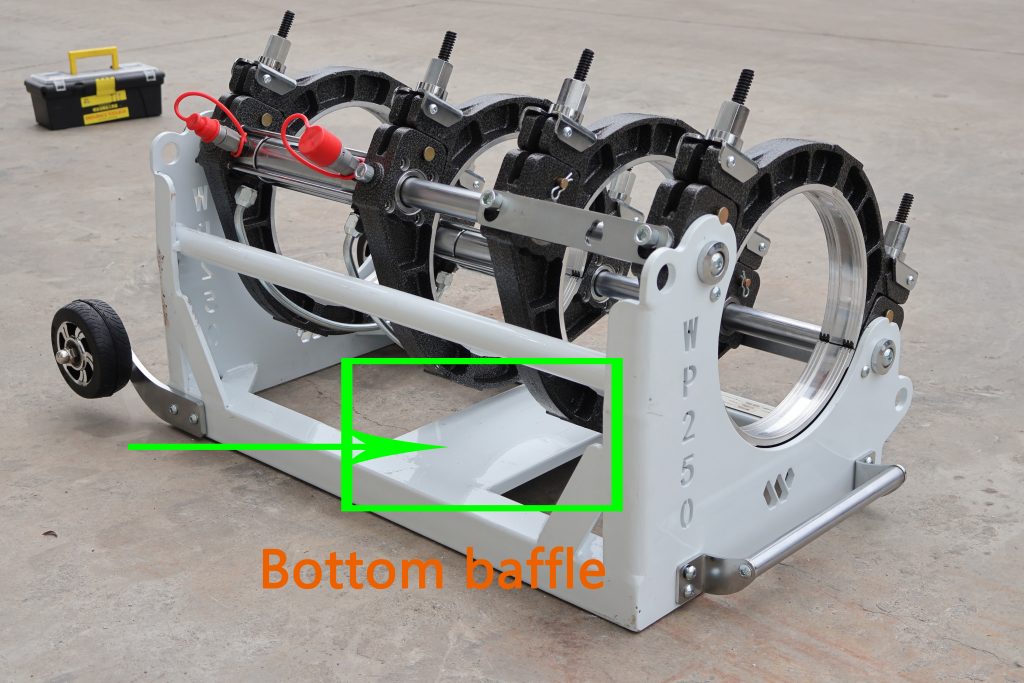

6.A new baffle design is added to the bottom of the basic frame , effectively preventing dirt and debris from getting into the butt weld ports during the milling process. This improvement not only improves the cleanliness and operational stability of the machine, but also reduces the frequency of maintenance and increases the service life of the machine.

7.Increase the anti-wear gasket at the locking place of the ring screw on the frame, and the stainless steel material is sturdy and durable.

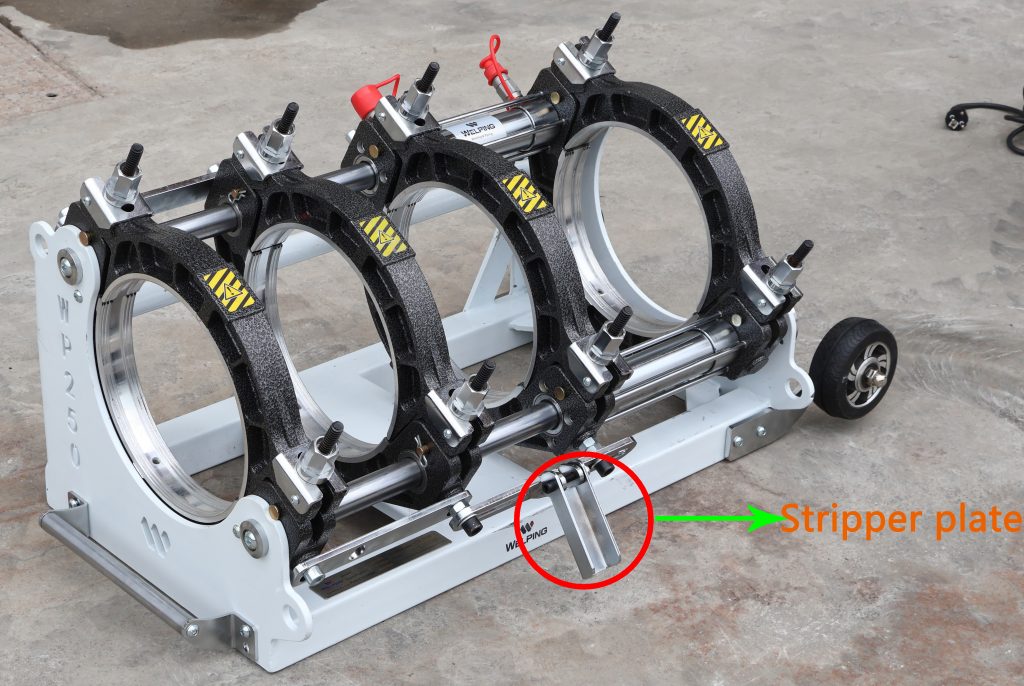

8.315 and above models of the Apro series added to the dismantling plate, the heating plate can be assisted to dismantle after the completion of the work, reducing labor consumption.

9.Basket sealing plate heightened design, low-temperature environment to effectively reduce the heat loss of the heating plate, shorten the preheating time, and enhance the safety to prevent accidents.