First of all, let’s talk about the heat fusion theory of butt welding machine.

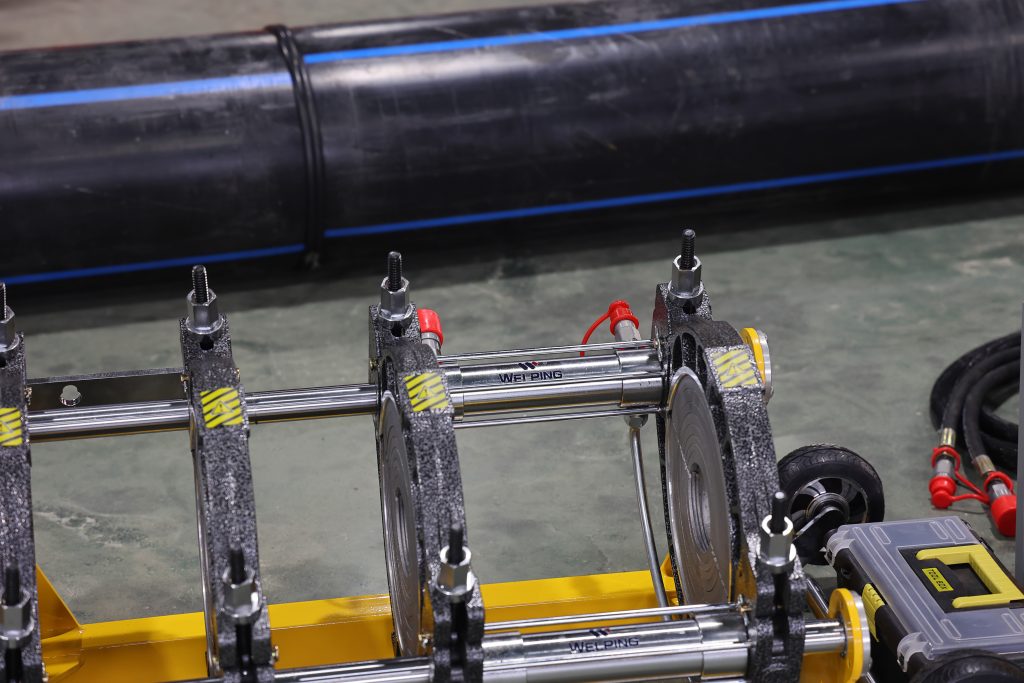

The pipe fusion process associated with Welping butt fusion machines is a widely accepted process that joins two pieces of thermoplastic pipe or pipe fitting together with heat and pressure. While commonly associated with high-density polyethylene pipe (HDPE), our machines are capable of fusing (or welding) a variety of different types and sizes of pipe including medium-density polyethylene (MDPE), polypropyleneand polypropylene-random (PP-R)

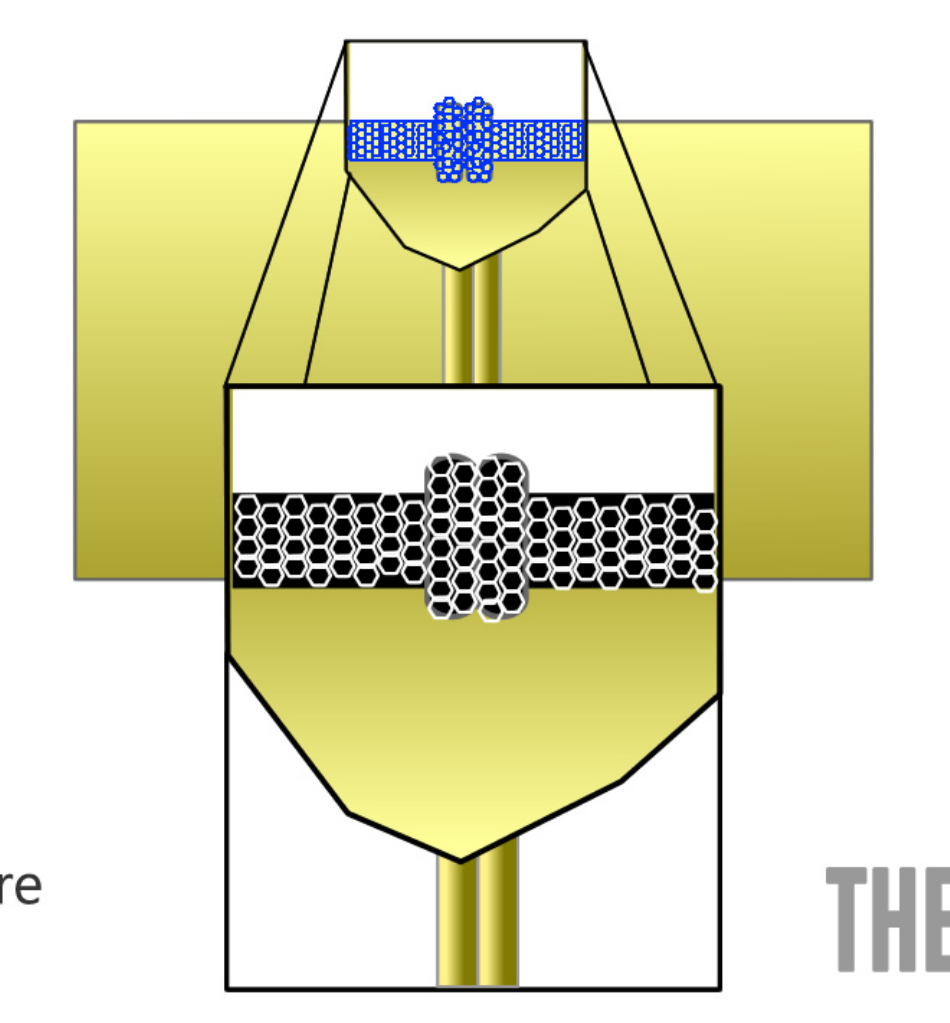

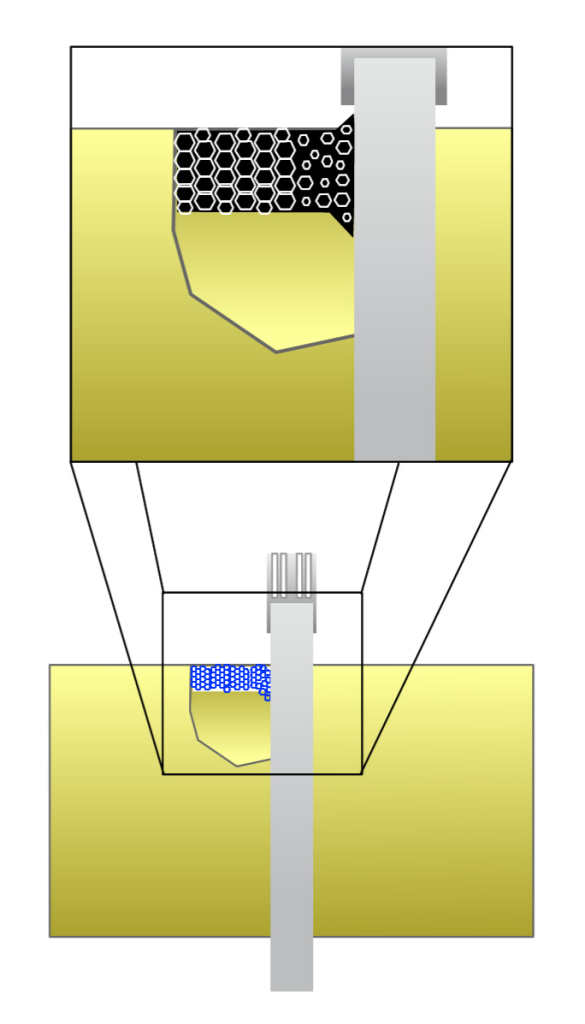

PRINCIPLES OF HEAT FUSION

Heating two surfaces to a designated temperatureand then joining them by applying force. This process generates pressure, leading to the flow and irtermingling of the melted materials, which resultsin fusion.When a thermoplastic pipe is heated, itsmolecular structure shifts from a crystalline state to an amorphous state.Upon applying fusion pressurethe molecules from each pipe end blend together.

What’s the result of heat fusion?

As the joint cools, the molecules revert to theioriginal state, eliminating the initial interfacesand resulting in a single, seamless pipe.

Why use butt fused pipe?

Heat-fused thermoplastic pipe has many benefits over traditional piping sustems.

- Seamless:Fused thermoplastiapipes form a monoithic pipeline with fewer mechanical transitions, reducing thelikelihood of leaks.

- Long Life:Thermoplastic pipessuch as HDPE, are expected to last up tc50-80 years, therebysaving on replacement costs.

- Cost-efficient:Heat-fused pipelinescreate leak-free svstems, reduce the neecfor maintenance or repairs, and conserve resources.

- Corrosion resistant : Thermoplastic pipesdo not rust or corrcde and are resistantto chemical abrasion

- Tough: Thermoplastic pipescan withstand common damages, vibrations, and pressure surges.