With the increasing popularization of pe pipe, pe pipe is being used in various fields such as petroleum gas, liquefied petroleum gas, water, drainage, electric power engineering, how to ensure the quality of engineering construction, buy good pe pipe, how to use pe pipe heat fusion welding machine in the engineering construction, how to skillfully master the engineering construction process, all of which are to ensure that the quality of engineering construction of the top priority.

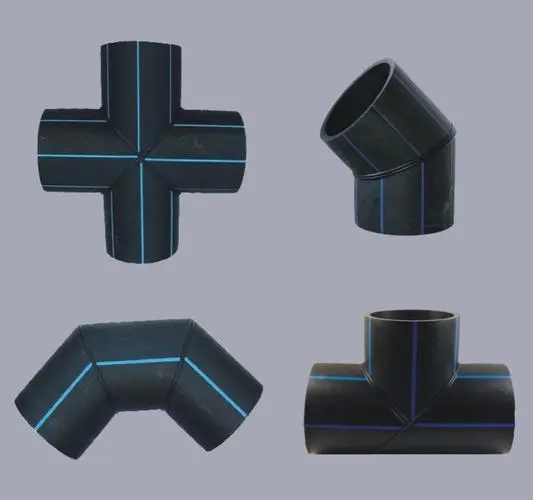

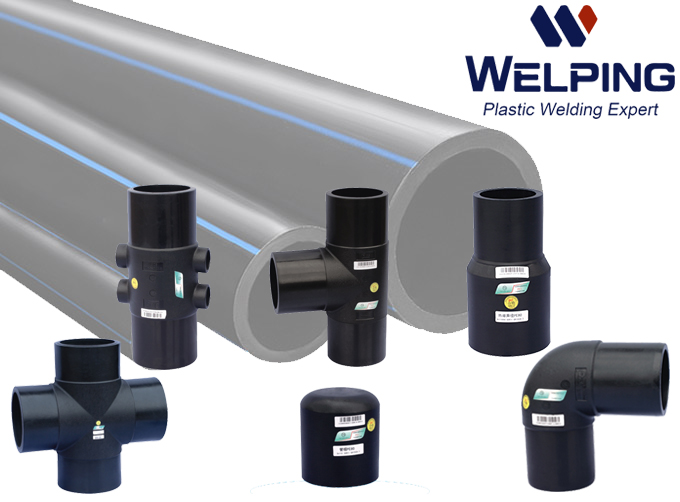

The pe pipe line itself has corrosion resistance, zero pollution, long service life easy to install, faster and so on.PE pipe line connected to the main two ways: with electric fusion connection and heat fusion welding.

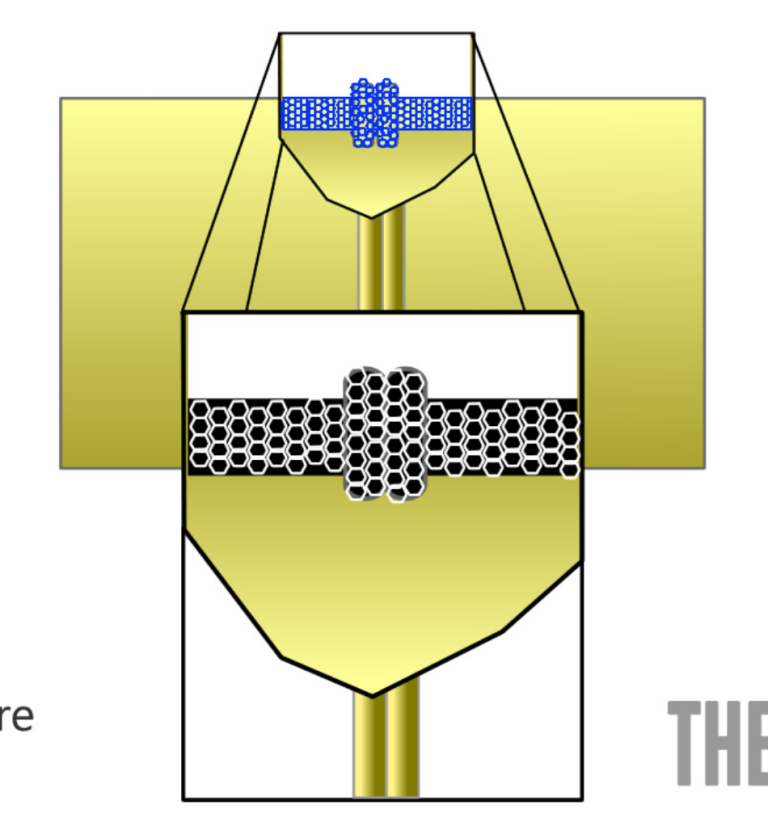

At this stage the main is mainly used to choose the heat fusion welding. The working principle of heat fusion welding is the two pe pipe line mating surface close to the electric heating special tool to electric heating its flat cross-section until melting, move away from the electric heating special tool, will be 2 melting cross-section close to a piece, in the extrusion pressure pressure to maintain to the connecting head after cooling, so that it becomes a whole, pe pipe line in the hot connection can be divided into socket and butt method of the two kinds of heat fusion connection methods, usually DE75 mouth through the following selection of socket heat fusion connection, need to use with socket socket, DE75 above the mouth through the selection of butt method heat fusion connection, pipe line socket heating heat fusion connection can be.

Hot fusion connection advance preparation. Thermal fusion connection Thermal fusion connection installation advance preparation tasks are shown below:

① Load clamping tiles of the same specification as the pipe into the machine frame;

② Prepare sufficient support items in advance to ensure that the pipe to be connected to the center line of the machine frame to be hot melt connection can be in the same height, and can be easily moved;

③ Set the temperature of the electric heating plate 200 ~ 230 ℃, usually around 210 ° temperature;

④Connect the power supply to the main machine of the hot melt welding machine, turn on the power switch of the electric heating plate, cutter and power oil pump and test run.