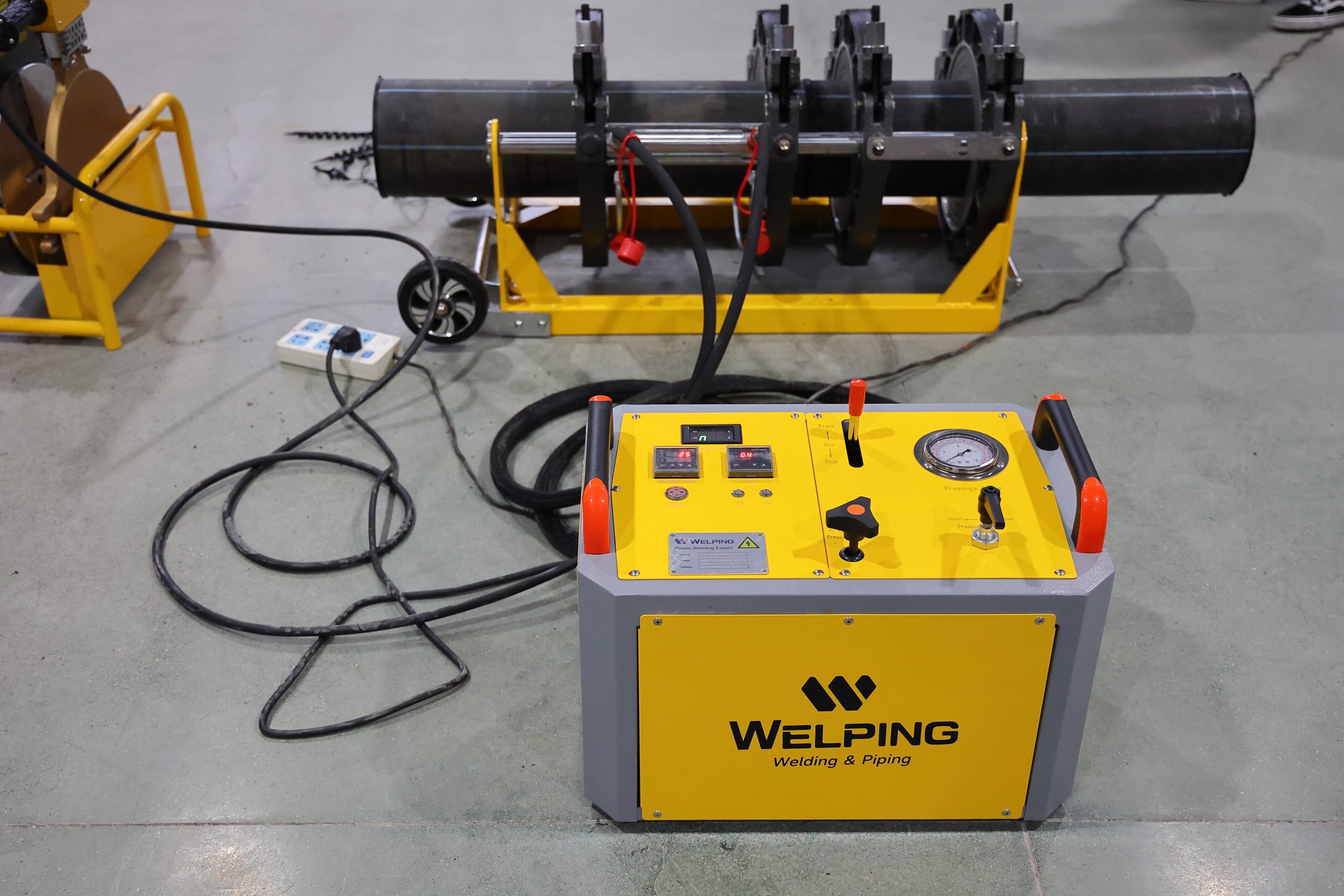

WP315A hydraulic butt fusion welding machine

The standard size of 160mm to 315mm, can extend to 90mm

Reinforced milling cutter with chain transmission

Support customization of color and branding

Product Description

Butt fusion welding stands out as a reliable and trouble-free method for connecting PE and HDPE pipes. In applications involving pressurized pipeline construction, butt fusion welding delivers outstanding performance, akin to a seamless pipe connection.

Model WP1600A standard includes a frame (carriage part) with reducers, a trimmer (facing tool), a heating plate, and a hydraulic station. The clamping and welding range can extend to 1000mm.

Product Features

1. Steel fabrication clamping sets of precision welding, strong and light-weight

2. Trimmer: durable copper wiring motor, HSS blade; Heating plate: PTFE coating from Daikin

3. Hydraulic station of integrated enclosure shielding splash and dirt, built-in high-quality electrical and hydraulic parts

4. Separate driving hydraulic cylinder part, easy for installation and service

| Model | WP315A |

| Welding range (mm) | 90-110-125-140-160-180-200-225-250-280-315 (mm) |

| Standard reducers (mm) | 160-315 |

| Optional reducers (mm) | 90-110-125-140 |

| Power supply | 220V/50Hz,1PH |

| Total power | 63 KW |

| Heating plate | 3.5 KW |

| Planing tool | 1.1 KW |

| Hydraulic station | 0.75 KW |

| Pressure adjusting range | 0-6.3MPa |

| MaxTemperature of heating plate | 270ºC |

| Temperature Deviation | ±5ºC |

| Piston area | 20.02CM2 |